Reducing stage sliding friction

First determine

if z stage needs to be a little wider or narrower by pushing firmly on

the plastic outward and inward (moving the rods about .05mm by

squeezing/stretching the entire stage). Use half or even all of

your finger strength. At the same time with the other hand slide

the zslider back and forth to see if friction is lower or higher.

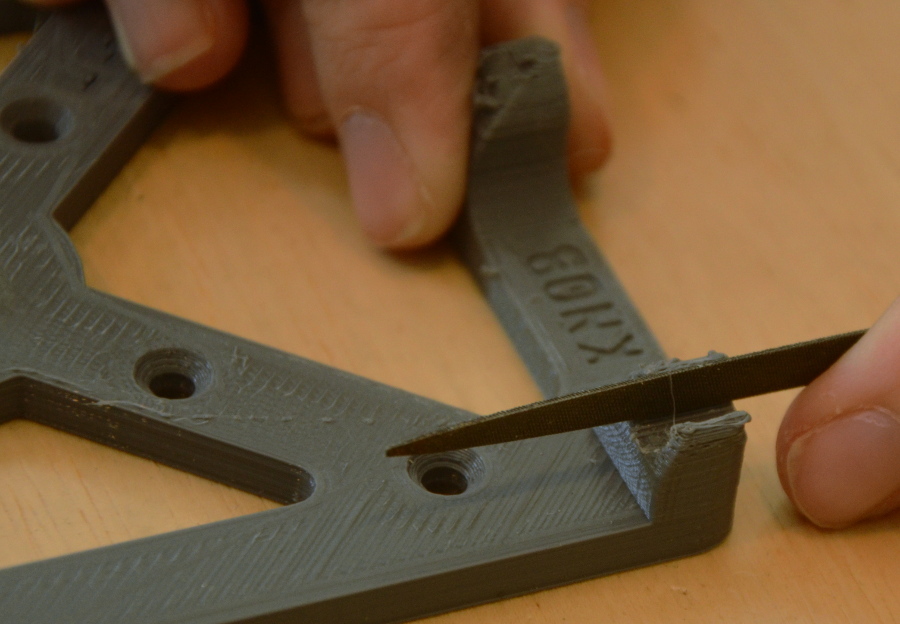

To disassemble pop it apart as shown below - insert file and twist.

If you had to

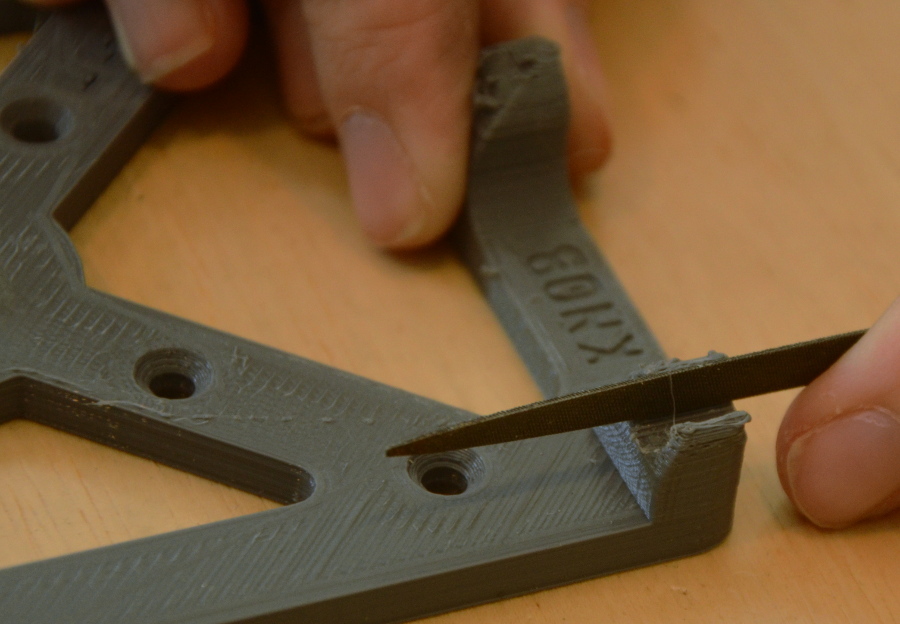

push outwards (move rods farther apart) then after disassembling file

the outside part of the z stage. If you had to squeeze the stage

inwards then file the inner surfaces that hold the rods as shown in

this picture

. It's super easy to get this backwards. The

way I think of it is that when you push hard on the lower part with

your fingers you are moving the rods and not the brass parts. When you file you need to again think of which way you want to move the rods

and file on the side that you want the rods to move towards. You

really shouldn't have to do any of this as we do this for you before

shipping the kits.

You really need a curved file as shown.

Reassemble and repeat as necessary. Sometimes one side needs more filing than the other.